Autumn is upon us once again, well actually high summer but the blackberries aren’t playing their usual ball this year. All good for me though because it means i can get a head start on my blackberry port making project.

Step one – go out and collect a huge amount of blackberries! I am planning on making a 5 gallon buckets worth of the stuff and for the recipe i found that means collecting industrial quantities (15 to 20 kilos!)

First one hour session of picking i managed….. 1.8kg. looks impressive but having to do that another 10 or so times may not be feasible. Time to call in the reinforcements.

Several trips later and we are now at the start of autumn and just as the blackberry season seems to be hitting its peek I have hit my target of 16kg. The recipe I’ve found calls for 4kg of blackberries per gallon of port and while the original plan was to make 5 gallons I’ve thought better of it. Because of the fortification and the back sweetening I need space left to add volume to the mix and I only have a 5 gallon bucket!

Step 1 – Making a Blackberry mix

So now we have all of our ingredients its time to begin. First things first you want to line your bucket with a fine mesh cloth. I used a cheese cloth for the inside and then a cider press bag for the outside to add strength to my ‘blackberry tea bag’. Add all of your blackberries to this and then add 2 litres of boiling water for every 4kg of blackberries and 1kg of sugar. So for me that was 16kg of blackberries, 8 litres of boiling water and 4kg of sugar.

Once you have everything in there you need to start crushing up all those juicy berries to get all that flavour out into your mixture.

I started off with a potato masher and then realised that wasn’t going to be long enough or robust enough. So out to the shed I went and found the cleanest looking wooden post I could find and then rinsed it with boiling water before using it to pulverize my mix together.

This was all made easier because the blackberries had been frozen, which helps to break down the fruit, and the sugar adds a bit of grit for the initial grinding and then after it has dissolved continues to help draw the juices out.

The final stages for this step are to add a campden tablet per gallon to the mix (so 4 tablets in my recipe) to stop any of the natural yeasts starting to ferment the mix before you are ready. Also you want to had half a teaspoon of citric acid per gallon to give the flavour at the end a little extra level of complexity.

Tie up the top of your cheese cloth to stop any rogue blackberries escaping and leave this mix for 24 hours to let the campden tablets do their thing.

Step 2 – Pectolase

After you have left it for 24 hours its time for another small step, Adding pectolase to the mix. Half a teaspoon per gallon. This prevents any pectin in the fruit trying to set and making your port turn cloudy later on. Great for jams but not so good for port.

Also have a check at this stage just to see that there are no bubbles forming on the top suggesting that fermenting has begun. The campden tablets should take care of this but no harm in checking.

Leave this to work for another 24 hours.

Step 3 – Take a Hydrometer Reading

Now if you are just making a rough country wine and you don’t really mind what the strength of it is then you can skip this step but for this recipe I was after a specific abv. (alcohol by volume) of 20% and so I needed to know what percentage my wine was before I turned it into port.

Just as a mini lesson on hydrometers. They are essentially a stick with a weight in the bottom and a scale running up the side. If you dropped it in plain water it would rest at one.

As you can see when I drop it in to the mix just before adding the yeast it sits much higher at 1.106 . This is because at the moment its got 4kg of sugar in (and is tasting really nice!). This makes the water dense and so the hydrometer floats higher.

As the sugar gets consumed by the yeast and turns it in to alcohol the density of the mixture decreases and so the hydrometer will sink more.

At the end of fermentation we are looking for that measurement to be back down around the 1 mark or perhaps even lower.

Step 4 – Time to get Brewing

Everything is ready now for you to start turning all that sugar you put in at the beginning, in to alcohol.

Because we are looking to make a port, which traditionally is around 20% abv, we are using a specialist high alcohol brewing yeast. The higher we can get our alcohol level at this stage the less brandy we will have to put in later to fortify it saving us money on the finished product.

So add your yeast to the brew and give it a good stir. I just bought a packet that was good for 5 gallons for my 4 gallon mixture. I added all of that to the mix and then put my air release through the lid of my bucket to let excess gas escape without letting in any dust.

This is where your patience comes in. You have to give the yeast time to do its thing. This will mostly rely on the temperature. If you can keep it toasty warm then the yeast will do its work quickly and happily and in about 5 days it could have consumed all the sugar.

If like me on the other hand you have to keep it out in the shed in the autumn it will take a little longer for the magic to happen.

After a week I was checking it with the hydrometer daily and once it got down to around the 1 mark, on day 11, I knew it had finished fermenting.

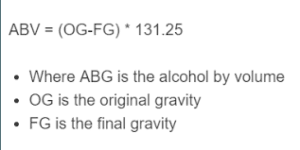

Once fermentation has completed you should take a hydrometer reading so that you can compare the original reading to this one and apply the following formula to find out what percentage your brew finished up at.

For me it was (1.106-0.993) * 131.25 which gave me an alcohol level of 14.8% which I was quite happy with.

Step 5 – Fortifying and Back Sweetening

Once the bubbles on the top of the mixture have calmed down and you don’t see any more bubbles coming through your airlock, you can be fairly sure that fermenting is complete. However to do these next steps you are going to have to make sure, so add one campden tablet per gallon of liquid to make sure that fermentation comes to a halt. Make sure you leave for 24 hours to do its job.

Then you need to turn it in to a proper fortified wine by getting the alcohol level up to 20%. I like to aim originally for around about the 22% mark because you are going to be diluting it a little with the back sweetening and so once done it should come back down to around the 20% mark.

To fortify it you are going to need some stronger alcohol. Traditionally brandy is used and my recipe was no exception. I chose to use a cheap brandy as the idea of this project for me was to try and save money, and the true flavour should come from the blackberries. Even though I forked out some money for the initial equipment, It is still going to work out at half the price of port from the shops and if I do it again the price is going to go down significantly because there is no need to buy a lot of the stuff twice (bucket, hydrometer etc).

After using an online pearson square calculator I calculated that i would need about 8 700ml bottles of 38% proof brandy.

Then you want to back sweeten your port. Port in my mind should be sweet, rich and fruity so it is essential for the flavour to do this step. The campden tablets should stop any sugar you add now turning in to alcohol.

Mix a sugar syrup using roughly 1 part sugar to 1 part boiling water. Then, to avoid ruining the whole batch by accident, take out 10% of it, or any scalable amount, and start adding small amounts of the sugar syrup tasting as you go. Once you have found that delicious flavour that is just right for your pallet stop and scale it up to the whole batch.

For me I like a sweet port and so ended up adding 4 litres of the sugar syrup to my 27 litre blackberry wine and brandy mix.

And now your port is ready for bottling and enjoying. Save for a cold winters night or give away as gifts if you so choose. Personally this first batch is just for me.

Facts and Figures

Just as an add on really I wanted to let you know some of the numbers involved for me in this batch.

In the end I used:

8kg of sugar (both for fermentation and back sweetening)

16kg of blackberries

8 bottles of 700ml brandy, 38% (by far the most expensive bit)

Re-useable equipment bought – fermentation bucket with a tap, 5 1 gallons jugs, 6 airlocks and hydrometer.

Brewing Consumables – yeast, pectolase, citric acid, campden tablets, stabiliser, wine finings.

Total cost – £170 (brandy being £112 of that)

Quantity of port made was 31 litres which equates to about 44 700ml bottles of port bringing the cost to around £3.86 per bottle.

Next year if I do the same thing then it will cost far less as I have left over campden tablets, pectolase, stabiliser and citric acid. I won’t need to buy the fermentation bucket or jugs again so the cost should come down to around the £120 mark, bringing the price per bottle down to £2.73.